B

A

V

-

C

B

c

r

u

s

h

e

r

b

u

c

k

e

t

s

Excavator Crusher Buckets

Crush away your rubble problems...

... with BAV-CB excavator crusher buckets

Recycling on site gives you independence from waste transport and materials deliveries. Excavator crusher buckets are a low capital outlay option for processing small volumes of waste rubble into aggregate.

Aside from reducing cost, it can eliminate time wasted for vehicles and reduce the nuisance and environmental impact of smaller work sites.

No more waiting for skips or tipper trucks to take rubble off site. No more waiting for crushed aggregates to be delivered to site.

Extremely handy on job sites that are:

- in highly congested areas

- in areas with tight or difficult access

- in environmentally sensitive locations

- surrounded by domestic properties

- a long way from quarry and/or recycling yards

No need for mobile tracked crushers or mini crushers.

* One machine

* One vehicle movement

* One operator

Recycle small volumes, on site, on demand.

Hardox® official

British Made

24 month warranty

Clear all

BAV-CB1 Mini Excavator Crusher Bucket 1.5-1.9t

INC. VAT £6,210.00 GBP

Excavator Model

INC. VAT £6,210.00 GBP

BAV-CB2 Mini Excavator Crusher Bucket 2.5-3.5t

INC. VAT £7,378.80 GBP

Excavator Model

BAV-CB5 Mini Excavator Crusher Bucket 3.5-6.0t

INC. VAT £11,230.80 GBP

Excavator Model

BAV-CB8 Midi Excavator Crusher Bucket 6.0-9.0t

INC. VAT £13,350.00 GBP

Excavator Model

BAV-CB12 Excavator Crusher Bucket 10.0-16.0t

INC. VAT £26,118.00 GBP

Excavator Model

G

e

t

t

h

e

B

A

V

-

C

B

a

d

v

a

n

t

a

g

e

01

Ultra Compact

02

Large capacity, powerful action

03

One machine, one operator

01

Ultra Compact

02

Large capacity, powerful action

03

One machine, one operator

BAV-CB Product Features

Details that deliver the difference

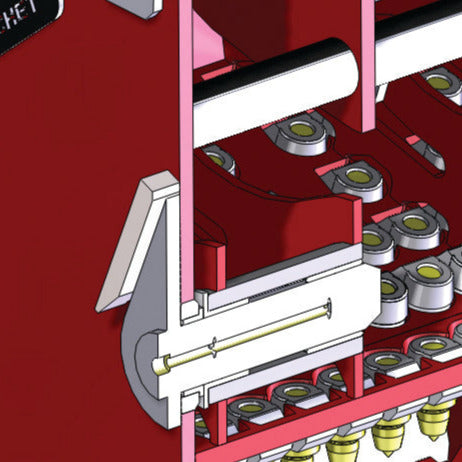

Hardox® 450 Construction

Chassis, moving jaw and crush grid are all fabricated from Hardox® 450 for high wear resistance, excellent yield strength and reliable durability.

- 3 to 4 times wear resistance of mild steel

- More than 4 times stronger than mild steel

Fully Bushed Pivots

All units feature hardened steel top-hat style bushings at the main jaw pivot, in both jaw and chassis fabrications, for long service life.

The top-hat style bush not only counters radial loads during jaw rotation, but also gives a replaceable thrust face for axial loads from crushing

(sectional view, 3D CAD render)

Tungsten Carbide Teeth

Custom designed tungsten carbide teeth give aggressive penetration and are also quick, cheap and simple to change.

Easy to swap out, even on site, so you can maintain maximum crushing performance and efficiency.

Adjustable Crush Grade

Removable grids on models BAV-CB5 and upwards, which enable two grades of output to be achieved;

- fine grade 0-50mm or coarse grade

- 0-100mm for faster processing speed.

BAV-CB1 & CB2 are fixed 0-50mm output size.

24 Month Warranty

The Hardox® chassis and main crushing jaw are guaranteed against failure of materials or workmanship for 24 months.

Guarantee excludes normal wear and tear to teeth, crush grids and ram seals and accidental damage.

British Built

Quality materials and skilled, British fabrication and manufacture ensure reliable, durable service life.

We are a British company, with a physical location within the UK that anyone can see on Google maps. You know who you are dealing with.

We've been building excavator crusher buckets since 2010, so have plenty of experience and history in the field. Our crusher buckets get good resale values, because they are trusted to not only do the job, but also last well too.

Why use an excavator-mounted crusher bucket instead of a mobile crusher? Watch the video below to look at some of the considerations.

Crusher Bucket FAQs

How much will it crush?

For most of our BAV-CB crusher bucket range,the very short answer is; approximately the weight of the carrier excavator, per hour. It can be faster than this in optimum conditions.

For more detail, please read further FAQ notes on output size and feed material.

What is the output grade size?

Other than the smallest two crusher bucket models,the BAV-CB1 & BAV-CB2, buckets have two output grade adjustments.

Grade is adjusted by add or removing a crush grid from the bucket. The grade with the grid fitted is the finest setting:

- Fine setting 0 to 50mm approx.

- Coarse setting 0 to 100mm max.

On the CB1 & CB2 it is only the 0 to 50mm grade available.

It will always take more time and energy to crush to a smaller grade. The finer,smaller output grade will always be slower.

Feed material type

For these types of crusher bucket, the ideal is good, clean, general grade concrete.

Things like driveways, between 100 and 150mm thickness, broken into roughly 300mm x 300mm sections.

Softer material like brick or breezeblock does not crush as cleanly (it crumbles) and is less dense, so it stands to reason the tonne-per-hour rate will be lower.

Very hard concrete or rock will also require more energy to crush

(some rock may even be too hard for the attachment) and hence will be slower. Finally, reinforcing in concrete can significantly slow down the crushing process.

Feed material size

Ideally, bricks, blocks and general grade concrete. Things like driveways, between 100 and 150mm thickness and broken into roughly 300mm x 300mm sections.

In a quarry, a lot of time and effort goes into engineering the blast to deliver optimum sized feed for the crushing plant, even if it's a very large 100+ tonne per hour unit.

For our crusher buckets, chunks which approach the maximum feed thickness or (to a lesser degree) width of the crusher bucket jaw will tend to present more difficulty. Very small items like small paving blocks can also be a bit slower to crush, because they pack out the jaws.

The ideal is middling-sized pieces. Large, awkward-shaped or very hard pieces are generally best left to one side, to crush once the rest of the material has been processed,in order.

Ideally, having a hydraulic hammer or breaker to reduce oversized or very hard pieces will help greatly.

Feed material quality & cleanliness

Many of our customers have hared similar stories of badly sorted material.

A typical example would involve them being called in to site to crush “about 200 tonnes of rubble” and arriving to find roughly 100 tonnes of good, crushable feed material, mixed in with roughly 100 tonnes of soil, dirt or fines.

This is not ideal. As far as possible, in order to maximise performance, feed material should be clean of dirt and fines and dry - an attachment such as our BAV-RS screening buckets can help.

Excavator auxiliary hydraulic requirements

This part is very simple. Always run on 2-way circuit not hammer circuit.

Flow: The attachments are designed to be able to take the maximum flow of their respective carrier excavator class. the more flow, the faster the jaw moves.

Pressure: The attachments are designed to be able to take the maximum pressure of their respective carrier excavator class. ensure your machine's circuits have not been re-set or de-rated. This will lead to poor performance.

On older machines, check the condition of hydraulic oil and also the pressure and flow performance of the pumps. Other digging functions can still work, even when pumps are worn out.

What routine maintenance is required?

Firstly and most importantly, grease all pivot points, every day. Use good quality, high load Lithium complex grease.

All carbide tips should be sharp for optimum penetration and efficiency. Check and replace badly chipped or blunt items as necessary. This would usually only be 5 or 6 per year.

All pivot points are fully bushed, with oversized pins. With regular greasing, they should all last for at least 3 to 4 years without any replacements required.

These crushing buckets enable an excavator to produce a graded aggregate from site rubble and are currently available for any digger from 2.5 to 16 tonnes with either a two-way auxiliary hydraulics (standard attachment circuit) or basic hydraulic hammer/breaker circuit, using our Auto-Crush valve.

The powerful, low-frequency, high-force crushing action allows even the hardest concrete to be processed with ease and will even cope with rock. This crushing process is highly resistant to blockages - thereby minimising costly downtime - and enables use on the widest variety of materials. The design has no vulnerable parts or machinery on the bucket sides.