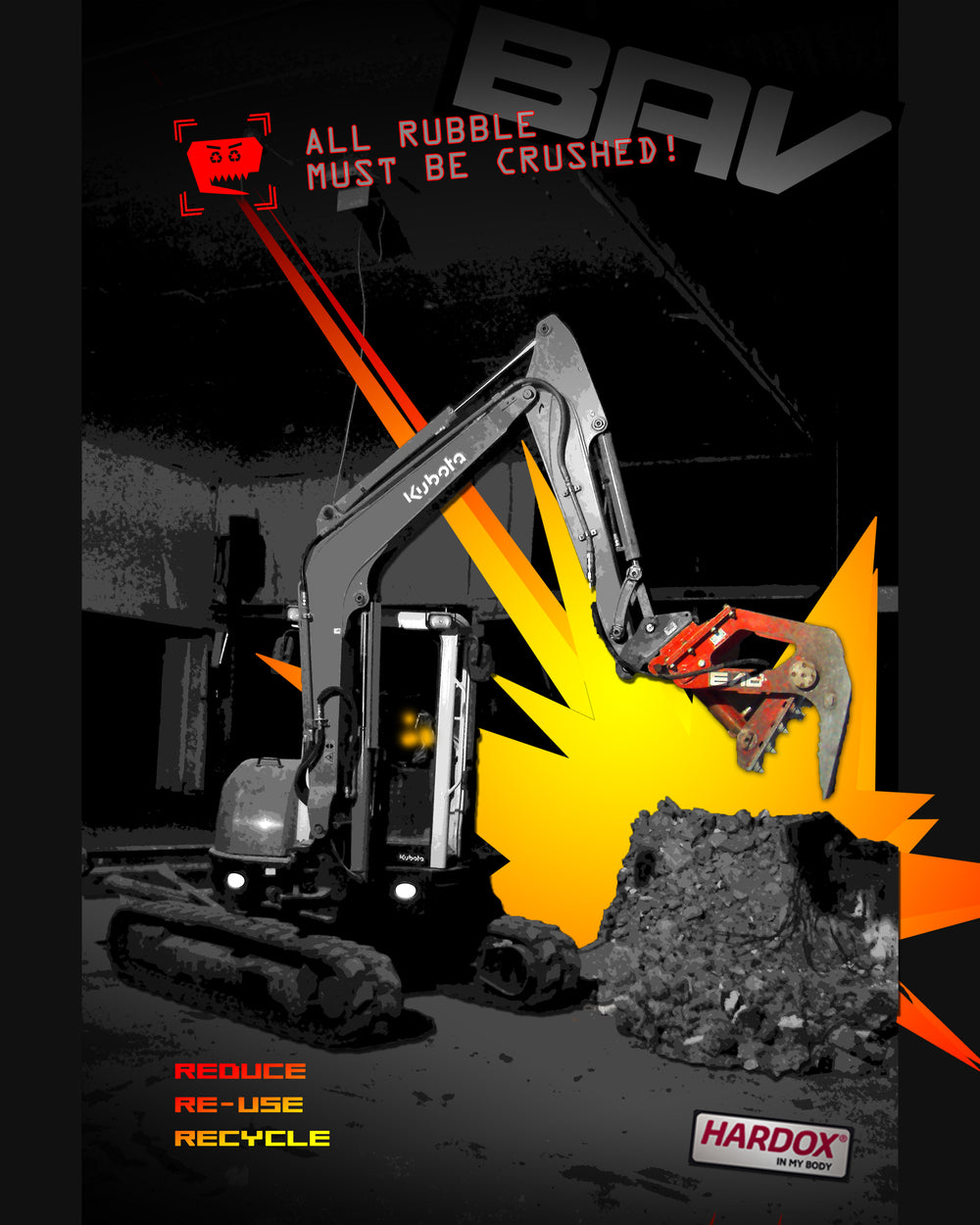

BAV3 Alligator Crusher for mini excavators 2.5-9.0t

INC. VAT £5,874.00 GBP

This mini or midi excavator mounted jaw crusher/pulverisor attachment, can do the lot. The BAV3 can break-up large chunks of material, cut reinforcing wire and can also produce a grade suitable for re-use on site.

This is all-in-one recycling tool is ideal for any confined site where the processing power of a full-sized machine is required.

Features:

- Tungsten carbide teeth

- Hardox® main plates

- Reinforcing wire cutters

Specifications:

- Weight: 365kg

- Carrier excavator size: 2.5 to 9 tonne mini & midi

- Jaw opening: 290mm

- Jaw length: 600mm

- Jaw width: 410mm

24 month warranty on jaw and chassis.

Please allow 3 to 4 working days for manufacture of excavator top bracket & PDI.

INC. VAT £5,874.00 GBP

BAV3 Alligator Crusher for mini excavators 2.5-9.0t

Title

G

e

t

t

h

e

B

A

V

3

a

d

v

a

n

t

a

g

e

01

Large jaw opening

Crush slabs over 250mm thick

02

Reduce waste volumes when removing from site. Create recycled aggregate to re-use on site.

03

Crush reinforcing mesh clean of concrete for best scrap value. Cut reinforcing wires.

01

Large jaw opening

Crush slabs over 250mm thick

02

Reduce waste volumes when removing from site. Create recycled aggregate to re-use on site.

03

Crush reinforcing mesh clean of concrete for best scrap value. Cut reinforcing wires.

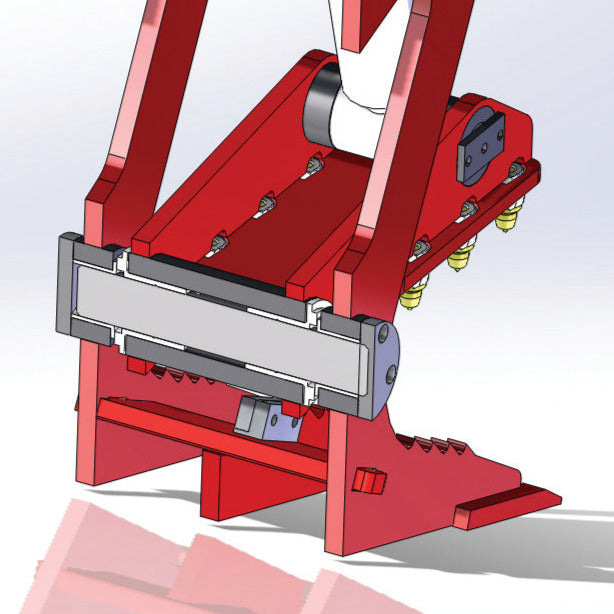

Introducing the BAV3

Alligator Crusher

Jaw pulveriser attachment for excavators 2.5 to 9 tonnes

Minimum Carrier Excavator weight

2

.

5

t

o

n

n

e

s

Maximum Carrier Excavator weight

9

.

0

t

o

n

n

e

s

- Jaw Opening (max.)

- Jaw Width

- Weight (approx.)

- Hydraulic Pressure

- Hydraulic Flow

- 290mm

- 410mm

- 365kgs

- 190-210 Bar

- 30-100 l/min

BAV3 Product Features

Details that deliver the difference

Hardox® 450 Construction

Chassis, moving jaw and crush grid are all fabricated from Hardox® 450 for high wear resistance, excellent yield strength and reliable durability.

- 3 to 4 times wear resistance of mild steel

- More than 4 times stronger than mild steel

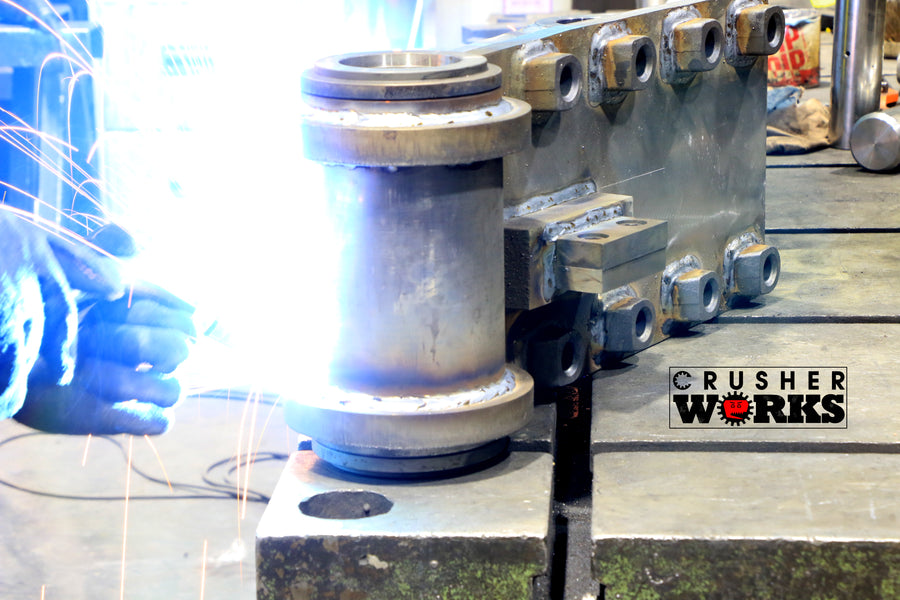

Fully Bushed Pivots

All units feature hardened steel top-hat style bushings at the main jaw pivot, in both jaw and chassis fabrications, for long service life.

The top-hat style bush not only counters radial loads during jaw rotation, but also gives a replaceable thrust face for axial loads from crushing

(sectional view, 3D CAD render)

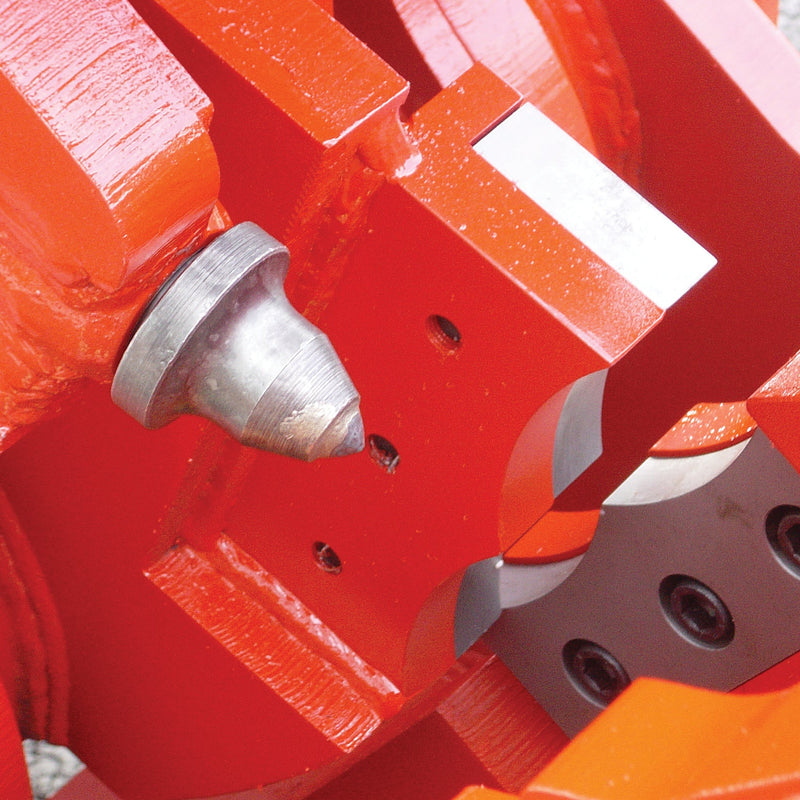

Tungsten Carbide teeth

Custom designed tungsten carbide teeth give aggressive penetration and are also quick, cheap and simple to change.

Easy to swap out, even on site, so you can maintain maximum crushing performance and efficiency.

24 Month warranty

The Hardox® chassis and main crushing jaw are guaranteed against failure of materials or workmanship for 24 months.

Guarantee excludes normal wear and tear to teeth, crush grids and ram seals and accidental damage.

British Built

Quality materials and skilled, British fabrication and manufacture ensure reliable, durable service life.

We are a British company, with a physical location within the UK that anyone can see on Google maps. You know who you are dealing with.

We've been building excavator crusher buckets since 2010, so have plenty of experience and history in the field. Our crusher buckets get good resale values, because they are trusted to not only do the job, but also last well too.

BAV3

The BAV3 Alligator Crusher attachment, for 2,5 to 9 tonne carrier excavators. The attachment will work faster and have more power when used on larger excavators, with better auxiliary attachment hydraulics.

Even on the smallest excavator, there is sufficient power for very hard concrete and also to cut reinforcing wires and rods.

Use a mini excavator-mounted jaw crusher pulverisor to process material that is too large or heavily reinforced for a mini mobile crusher. Watch the video below to see how.

May you also like

No products found